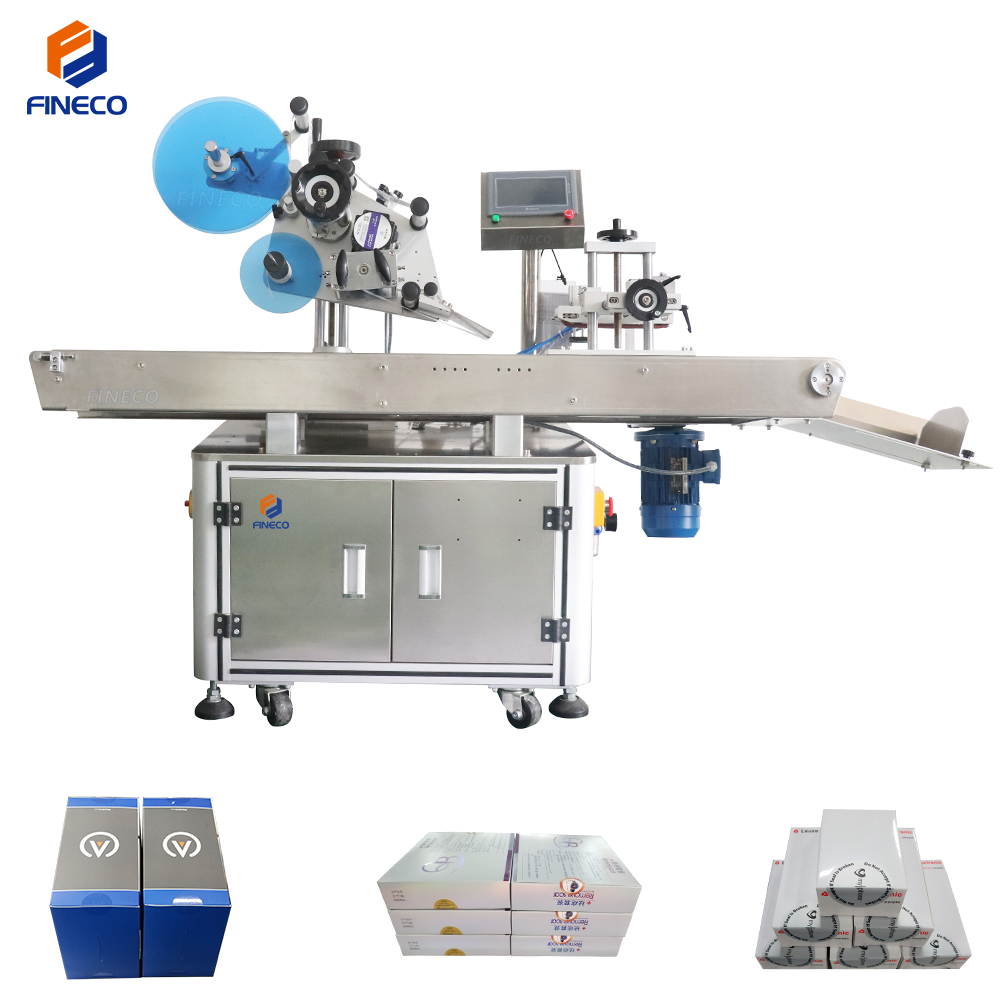

China Gold Supplier for Label Maker - FK816 Automatic Double Head Corner Labeling Machine – Fineco

China Gold Supplier for Label Maker - FK816 Automatic Double Head Corner Labeling Machine – Fineco Detail:

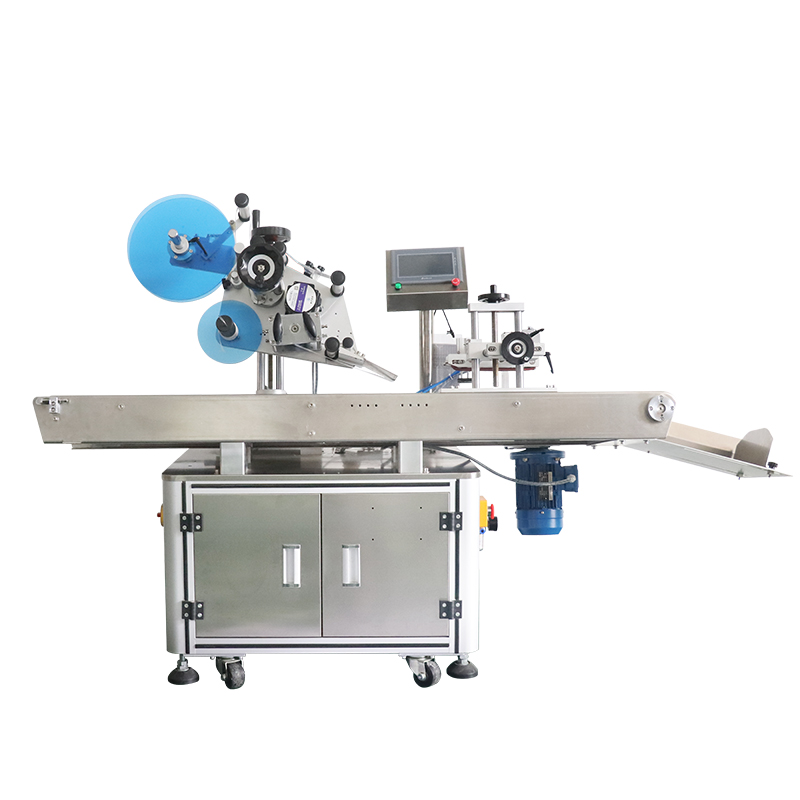

FK816 Automatic Double Head Corner Labeling Machine

Machine Description:

FK816 is suitable for all kinds of specifications and texture box such as phone box, cosmetic box, food box also can labeling plane products , refer to FK811 detail.

FK816 can achieve double sealing film labeling, full coverage labeling, partial accurate labeling, vertical multi-label labeling and horizontal multi-label labeling, widely used in cosmetics, electronic, food and packaging materials industries.

FK816 has additional functions to increase:

- configuration code printer or ink-jet printer, when labeling, print clear production batch number, production date, effective date and other information,coding and labeling will be carried out simultaneously.

- configuration printer,change printer contents at any time,realize the function of printing and labeling at the same time.

- Automatic feeding function (combined with product consideration);

- Automatic material collection function (combined with product consideration);

- Increase labeling device;

FK816 floor space about 2.35 stere.

Machine Support Customization.

The FK816 Double Head Corner labeling machine has simple adjustment methods, high labeling accuracy and good quality, Applicable to the requirements of high precision, high output products, and it is difficult to see the error with the naked eye.

Technical Parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance | ±0.5mm |

| Capacity(pcs/min) | 40~100 |

| Suit product size(mm) | L:20~300 W:20~250 H:10~100;Can be customized |

| Suit label size(mm) | L:15-200;W(H):15-130 |

| Machine Size(L*W*H) | ≈1450*1250*1330(mm) |

| Pack Size(L*W*H) | ≈1500*1300*1380(mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 1470W |

| N.W(KG) | ≈220.0 |

| G.W(KG) | ≈400.0 |

| Label Roll | ID:Ø76mm; OD:≤260mm |

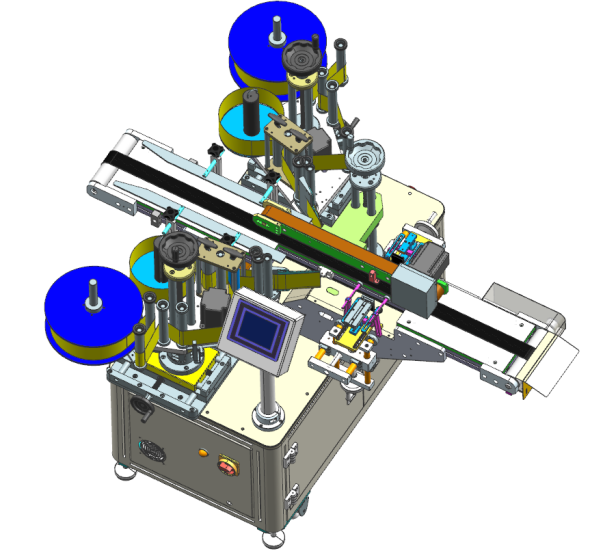

Structures:

|

No. |

Structure |

Function |

|

1 |

Guardrail mechanism |

Used to guide the direction of the product |

|

2 |

Conveying mechanism |

Transmit product |

|

3 |

Touch screen |

Operation and setting parameters |

|

4 |

Electric box |

Place electronic configurations |

|

5 |

Tray |

Place labels. |

|

6 |

Longitudinal adjustment |

used to adjust the up and down position of the labeling head and adjust the labeling position; |

|

7 |

Traction mechanism |

Driven by traction motor to draw the label |

|

8 |

Coping mechanism |

Fixed the product to make the product perpendicular to the conveyor belt to ensure the labeling accuracy |

|

9 |

Recycling mechanism |

recycling label bottom paper. |

|

10 |

Peel off the label |

peel off the label. |

|

11 |

Roller |

Wind the label roll |

|

12 |

Sensor frame |

install the target sensor, move the sensor back and forth. |

|

13 |

Longitudinal adjustment of the topping mechanism |

adjust the up and down position of the topping mechanism. |

|

14 |

Corner mechanism |

The corner of the label attached to the workpiece is pressed tightly. |

|

15 |

Positioning mechanism |

used to fix the position of the product and stabilize the label. |

|

16 |

Master switch |

Open the machine |

|

17 |

Indicator light |

refers to whether the labeling machine is powered on. |

Working Principle:

1. Click star on the touch screen.

2. The product placed next to the guardrail, then the conveyor belt moves the products forward.

3. When the sensor detects that the products has reached target location,the machine will send out the label and the roller attaches the half of the label to the product.

4. Then when the product is labeled and reached a certain position, the brush will pop out and brushes the others half of the label onto the product, achieve corner labeling.

Label Specification:

① Applicable labels: sticker label, film, electronic supervision code, bar code.

② Applicable products: Products that are required to be labeled on flat, arc-shaped,round, concave, convex or other surfaces.

③ Application industry: Widely used in cosmetics, food, toys, chemical, electronics, medicine and other industries.

④ Application examples: shampoo flat bottle labeling, packaging box labeling, bottle cap, plastic shell labeling, etc.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Features:

1) Control System: Japanese Panasonic control system, with high stability and extremely low failure rate.

2) Operation System: Color touch screen, directly visual interface easy operation. Chinese and English available. Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor, which are sensitive to label and product , thus ensure high accuracy and stable labeling performance. Greatly saves labor.

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions.

5) Machine Material: The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

6) Equip with a voltage transformerto adapt to local voltage.

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for China Gold Supplier for Label Maker - FK816 Automatic Double Head Corner Labeling Machine – Fineco , The product will supply to all over the world, such as: Namibia , Holland , United States , Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!