China New Product Heat Shrink Label Machine - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco

China New Product Heat Shrink Label Machine - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco Detail:

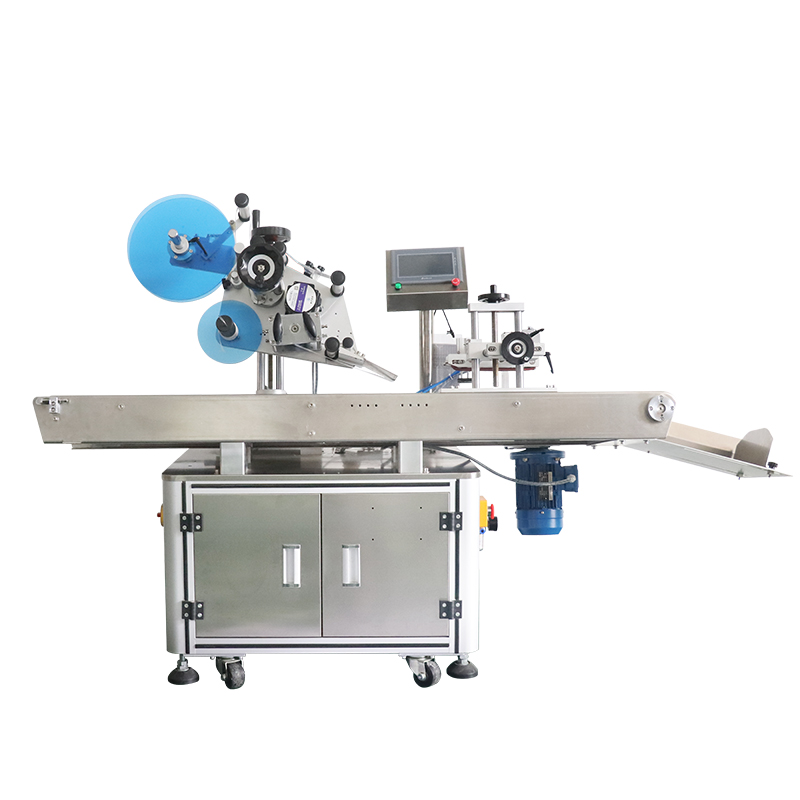

FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand

Customized and be installed on assembly line, labeling on upper plane and cambered surface of flowing objects.

FK838 automatic labeling machine has additional functions to increase options:

1. An optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

FK838 automatic labeling machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK838 automatic labeling machine covers an area of about 1.11 cubic meters

Support custom labeling machine according to the product.

Work Process:

FK838 automatic labeling machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK838 automatic labeling machine covers an area of about 1.11 cubic meters.

Support custom labeling machine according to the product.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Technical Parameters:

◆ Labeling accuracy (mm): ±1mm(errors caused by product and label are not concerned)

◆ Labeling speed (pcs / min): Step: 40~150pcs/min Servo:50~200pcs/min (influenced by the size of the product and label)

◆ Applicable Product Diameter: L: No Requirement (Depend on assembly line parameter)

◆ Suitable label size(mm): length: 10mm~250mm;Width:10mm~120mm

◆ Applicable power supply: 220V/50HZ

◆ Weight (kg): about 70kg

◆ Applicable standard roll Inner diameter (mm): φ76mm

◆ Applicable standard roll Outer diameter (mm): φ300mm

◆ Power(W): 330W

◆ Device dimensions (mm) (L × W × H): customized machine is subject to actual conditions.

Product detail pictures:

Related Product Guide:

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for China New Product Heat Shrink Label Machine - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco , The product will supply to all over the world, such as: Georgia , Malaysia , Gambia , Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!