Discount Price Auto Liquid Filling Machine - HM1A-2-1-000-FK807 automatic Nucleic acid testing tube filling Screw capping filling machine – Fineco

Discount Price Auto Liquid Filling Machine - HM1A-2-1-000-FK807 automatic Nucleic acid testing tube filling Screw capping filling machine – Fineco Detail:

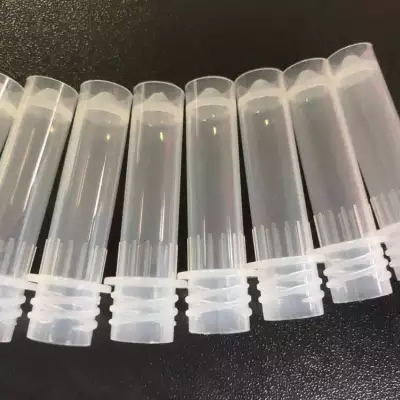

HM1A-2-1-000-FK807 automatic Nucleic acid testing tube filling Screw capping filling machine

Machine Description:

automatic Nucleic acid testing tube filling Screw capping filling machine is suitable for labeling various small-sized cylindrical and conical products, such as cosmetic round bottles, small medicine bottles, plastic bottles, oral liquid bottle labeling, pen holder labeling, lipstick labeling,and other small round bottles liquid bottle filling, capping and labeling etc. It is widely used in round bottle labeling in food, cosmetics, wine making, medicine, beverage, chemical industry and other industries, and can realize semicircular labeling.

1.Suitable for filling, capping and labeling test tubes, tubes, reagents and various small round tubes

2.Support customization

Another Functions to Increase Options:

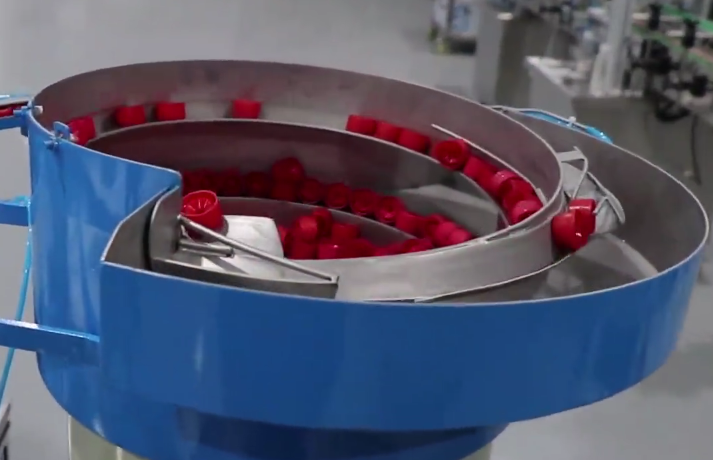

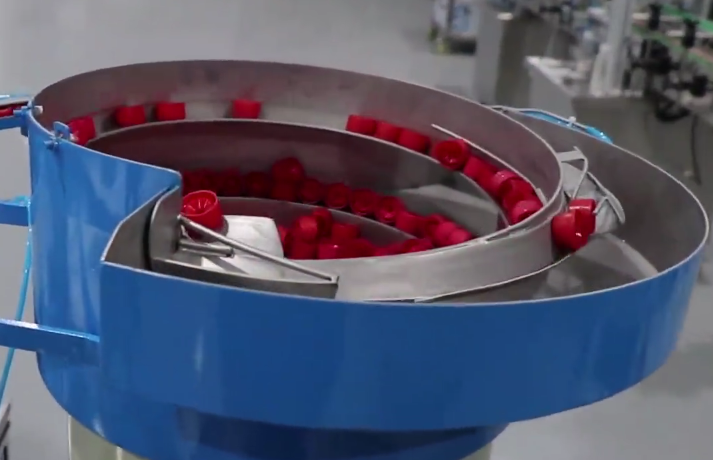

① Optional automatic rotary bottling machine.

② It can be directly connected to the production line to realize automatic bottling and improve production efficiency.

③ The optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging procedures and greatly improve production efficiency.

④ Automatic feeding function (combined with product consideration);

⑤ Automatic material collection function (combined with product consideration);

⑥ Increase labeling device;

Parameter

| Labeling accuracy | ± 1mm (excluding product and label error) |

| Filling + capping speed | 2500 ~ 3000 hours |

| Suitable diameter | Φ10MM ~ φ30mm (labeling) , Φ16MM (filling) |

| Applicable label size | length: 20mm ~ 250mm width: 20mm ~ 110mm |

| Suitable power supply | 220V 50/60HZ |

| Whole machine weight | about 600Kg |

| Inner diameter of label | Φ76MM |

| Suitable for outside diameter of label | φ300mm |

| Voltage (V) | 220V |

| Power | 3.0 kw |

| Size | labeling machine:2100mm × 750mm × 1400mm; filling machine :1200mm × 800mm × 1480mm (length × width × height) |

Structures

| Main electrical configuration of labeling machine | ||

| Electrical name | quantity | type and specification |

| Label sensor | 1 PCS | German |

| PLC | 1PCS | Japan |

| Touch Screen | 1PCS | Kunlun State |

| Traction Motor | 1PCS | China |

| Product sensor | 1PCS | German |

| Conveyor motor inverter | 1PCS | China |

| Main electrical configuration of filling machine | ||

| Electrical name | quantity | type and specification |

| Touch Screen | 1PCS | China shenzhen |

| PLC | 1PCS | China shenzhen |

| SUMTAK Sensor | 1PCS | China |

| Servo motor | 1PCS | Japan |

| Cam splitting | 1PCS | China |

| Speed Control Motor | 1PCS | China |

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Features:

1 ) Control System: Japanese Panasonic control system, with high stability and extremely low failure rate.

2 ) Operation System: Color touch screen, directly visual interface easy operation.Chinese and English available. Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor, which are sensitive to label and product, thus ensure high accuracy and stable labeling performance. Greatly saves labor.

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions.

5) Machine Material: The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

6) Equip with a voltage transformerto adapt to local voltage.

FAQ

Q: Are you the factory?

A: We are Manufacturer located in Dongguan,China.Specialized in labeling machine and packaging industry for more than 10 years,have thousands of customer cases,welcome for factory inspection.

Q: How to make sure your labeling quality is good?

A: We are using strong and durable mechanical frame and premium electronic parts such as Panasonic,Datasensor,SICK…to make sure stable labeling performance.What’s more,our labelers approved CE and ISO 9001 certification and have patent certificates.Besides,Fineco was awarded Chinese“New High-Tech Enterprise” in 2017.

Q: How many machines your factory have?

A: We produce standard and custom-made adhesive labeling machine.By automation grade,there are semi automatic labelers and automatic labeler;By product shape,there are round products labelers,square products labelers,irregular products labelers,and so on.Show us your product, labeling solution will be provided accordingly.

Q: What’s your quality assurance terms?

Fineco strictly implement responsibility of the post,

1) When you confirm order,the design department will send the final design for your confirmation before production.

2) The designer will follow the processing department to ensure each mechanical parts are processed correctly and timely.

3) After all parts done,designer transfer responsibility to the Assembly Dept,which need to assemble the equipment on time.

4) Responsibility transferred to Adjustment Dept with the assembled machine.Sales will check the progress and feedback to customer.

5) After customer’s video checking/factory inspection,sales will arrange the delivery.

6) If customer have problem during application,Sales will ask the After-sales Dept to solve it together.

Q: Confidentiality Principle

A: We will keep All Our Clients’ Design,Logo,and Sample on our archives,and never show to the similar clients.

Q: Is there any installation direction after we received the machine?

A: Generally you can apply the labeler directly once receive it,because we have adjust it well with your sample or similar products.Besides,instruction manual and videos will be provided.

Q: What label material does your machine use ?

A: Self-adhesive sticker.

Q: Which kind of machine can meet my labeling requirement?

A: Pls supply your products and label size (picture of labeled samples is rather helpful), then suitable labeling solution will be suggested accordingly.

Q: Is there any insurance to guarantee that I will get the right machine I pay for?

A: We are an on-site check supplier from Alibaba. Trade Assurance provides quality protection, on-time shipment protection and 100% safe payment protection.

Q:How could I get the spares of machines?

A: Non-artificial damaged spares will be sent freely and shipping free during 1 year’s warranty.

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients' higher comments for Discount Price Auto Liquid Filling Machine - HM1A-2-1-000-FK807 automatic Nucleic acid testing tube filling Screw capping filling machine – Fineco , The product will supply to all over the world, such as: Amman, Thailand , Cannes , Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.