Factory Outlets Double Side Sticker - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco

Factory Outlets Double Side Sticker - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco Detail:

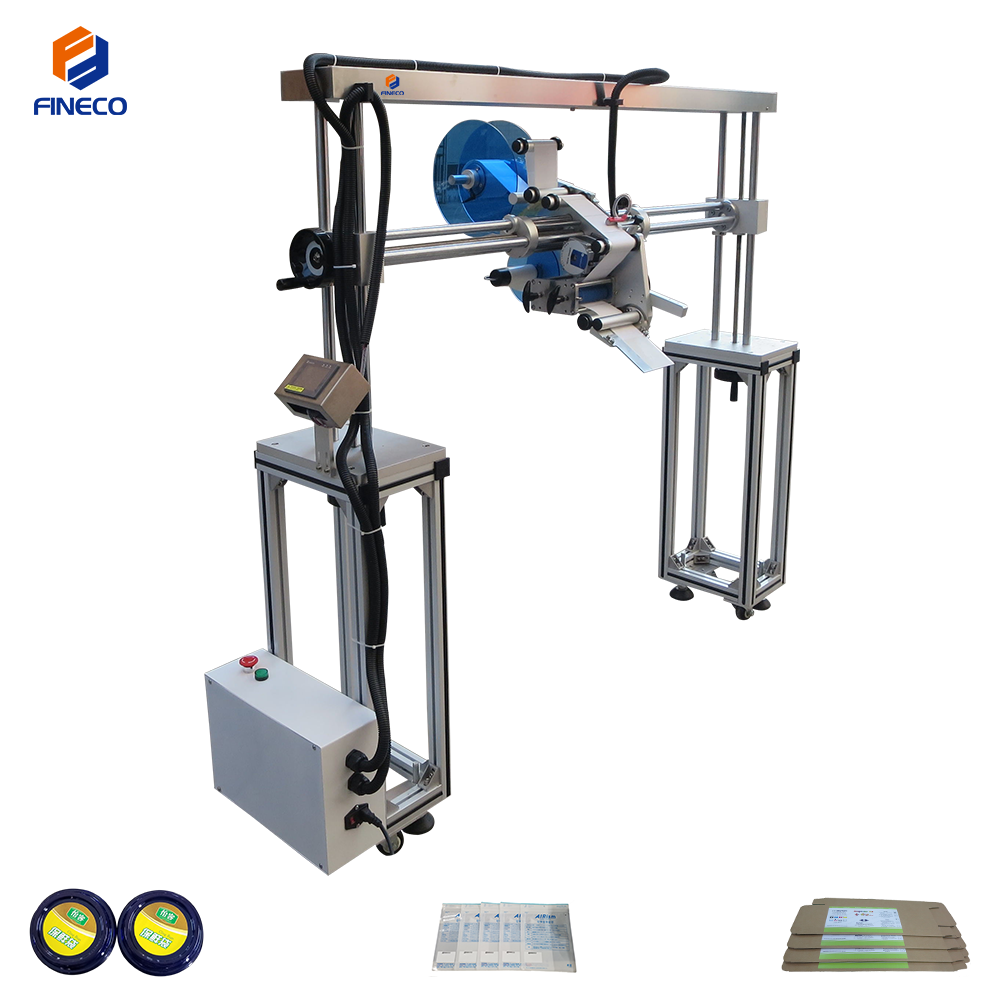

FK838 Automatic Portal Frame Plane Production Line Labeling Machine

You can set video sharpness in the lower right corner of the video

Customized and be installed on assembly line, labeling on upper plane and cambered surface of flowing objects.

FK838 automatic labeling machine has additional functions to increase options:

1. An optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

FK838 automatic labeling machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK838 automatic labeling machine covers an area of about 1.11 cubic meters

Support custom labeling machine according to the product.

Technical Parameters:

| Parameter | Data |

| Label Specification | adhesive sticker, transparent or opaque |

| Labeling Tolerance(mm) | ±1 |

| Capacity(pcs/min) | 40 ~ 150; servo:50 ~ 200 |

|

Suit product size(mm) |

L: 10 ~ 250; W:10 ~ 120. Can be customized |

| Suit label size(mm) | L: 10-250; W(H): 10-130 |

| Machine Size(L*W*H)(mm) | Make according to demand |

| Pack Size(L*W*H) (mm) | Make according to demand |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power(W) | 330 |

| N.W (KG) | ≈100.0 |

| G.W(KG) | ≈120.0 |

| Label Roll | ID: >76; OD:≤280 |

Work Process:

FK838 automatic labeling machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK838 automatic labeling machine covers an area of about 1.11 cubic meters.

Support custom labeling machine according to the product.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for Factory Outlets Double Side Sticker - FK838 Automatic Plane Production Line Labeling Machine with Gantry Stand – Fineco , The product will supply to all over the world, such as: Czech , Namibia , Armenia , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!