Free sample for Lyophilized Powder Labeling Machine - FK803 Automatic Rotary Round Bottle Labeling Machine – Fineco

Free sample for Lyophilized Powder Labeling Machine - FK803 Automatic Rotary Round Bottle Labeling Machine – Fineco Detail:

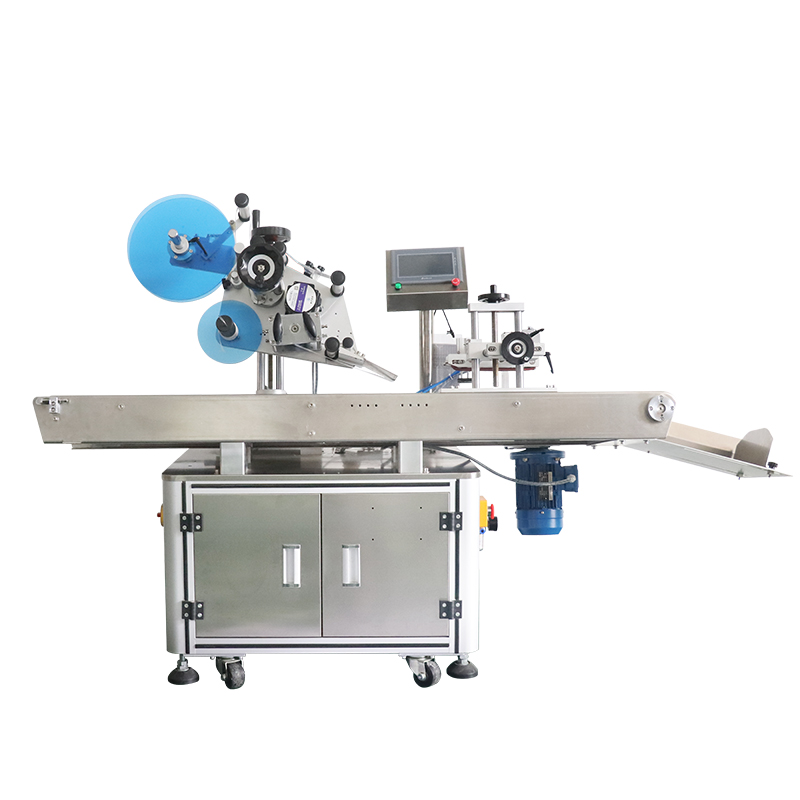

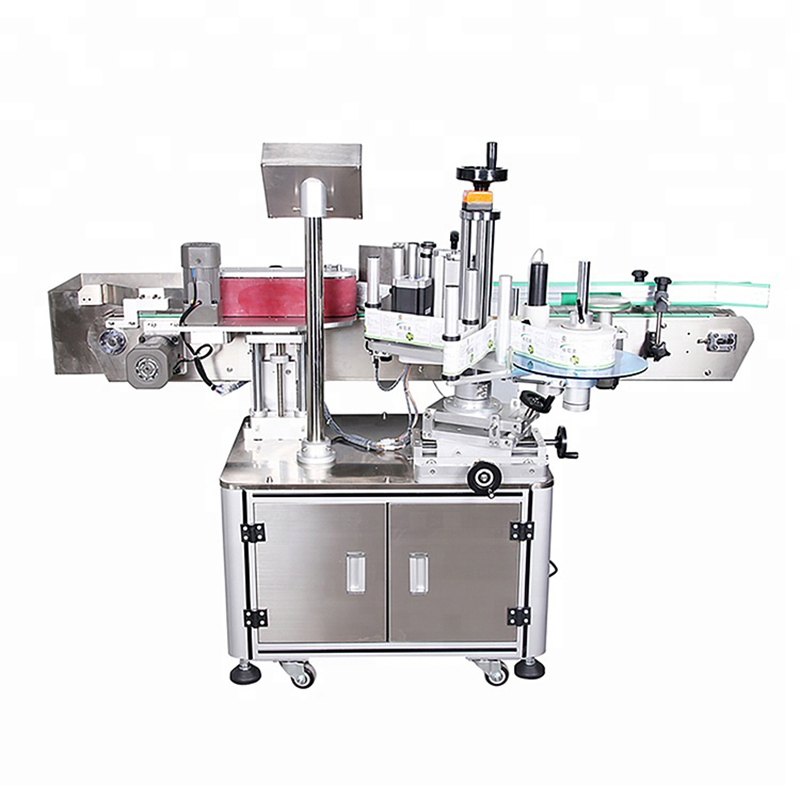

FK803 Automatic Rotary Round Bottle Labeling Machine

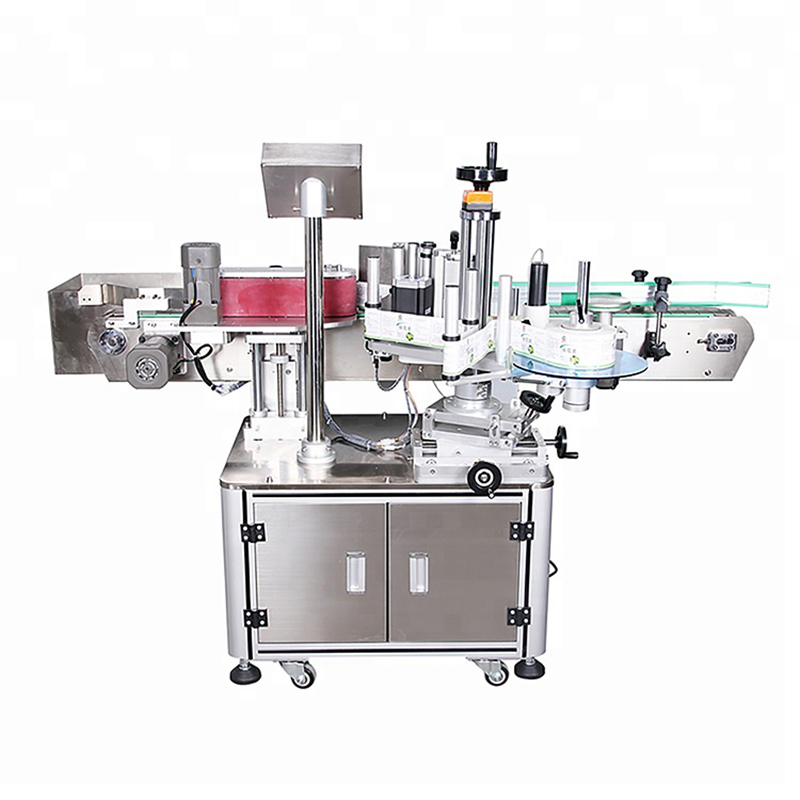

FK803 has additional functions to add options:

① Optional automatic rotary bottling machine.

② It can be directly connected to the production line to realize automatic bottling and improve production efficiency.

③ The optional ribbon coding machine can print production date, expiration date and production batch online, which reduces the bottling process and greatly improves production efficiency.

④ Automatic feeding function (combined with product consideration);

⑤ Automatic material collection function (combined with product consideration);

⑥ Increase labeling device;

The adjustment method of FK803 is simple, adopting the sponge belt labeling method, the labeling accuracy is high, the error is difficult to see with the naked eye, and it is the best choice for products that require high yield.

FK803 covers an area of approximately 2.92 cubic meters.

Support custom labeling machine according to the product.

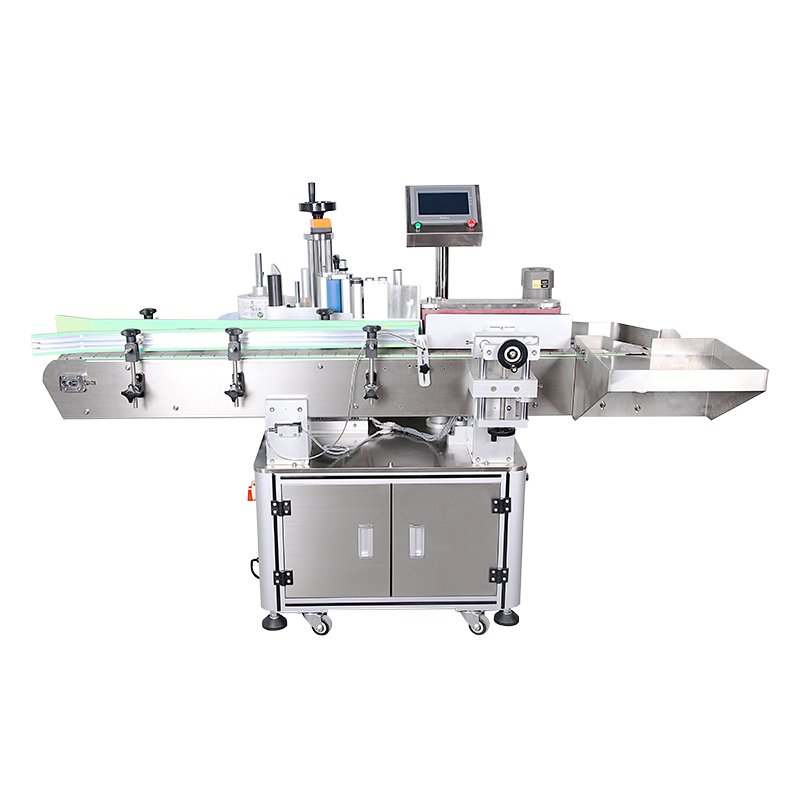

Work Process

Working Principle: The label sensor, product sensor send signals to PLC, where the signals are processed and sent to different parts such as motors, then labeling start.

Labeling Process: Feeding(can be connected to the assembly line) →Spacing→Detecting → Labeling→ Collection.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Technical Parameters

◆ Labeling accuracy (mm): ±1mm(errors caused by product and label are not concerned)

◆ Labeling speed (pcs / min): 30~80pcs/min(influenced by the size of the product and label)

◆ Applicable Product Diameter: φ25mm~φ100mm; Height:25mm~150mm(We can make it according to your sample diameter)

◆ Suitable label size(mm): length: 20mm~380mm;Width:15mm~100mm

◆ Applicable power supply: 220V/50HZ

◆ Weight (kg): about 45kg

◆ Applicable standard roll Inner diameter (mm): φ76mm

◆ Applicable standard roll Outer diameter (mm): φ300mm

◆ Power(W): 655W

◆ Device dimensions (mm) (L × W × H): about 1900mm × 1100mm ×1400mm

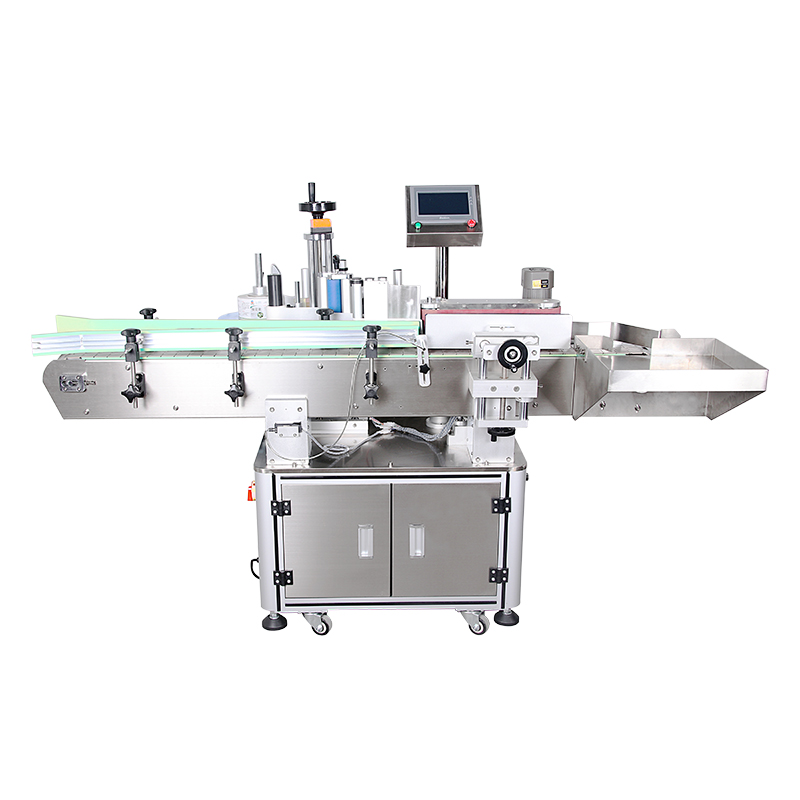

| No. | Structure | Function |

| 1 | Double Side Guardrails | keep the bottles goes straightly, can be adjusted according to the diameters of the bottles. |

| 2 | Labeling Head | core of the labeler, including label-winding and driving structure. |

| 3 | Touch Screen | operation and setting parameters. |

| 4 | Rotary Belt | driven by a motor to rotate products while labeling. |

| 5 | Electric Box | place electronic configurations. |

| 6 | Collection Plate | collect the labeled products. |

| 7 | Spacing Wheel | makes every 2 products keep certain distance. |

| 8 | Adjusters | used to adjust labeling position. |

| 9 | Emergency Stop | stop the machine if it runs wrong. |

Features:

1 ) Control System: Japanese Panasonic control system, with high stability and extremely low failure rate.

2 ) Operation System: Color touch screen, directly visual interface easy operation.Chinese and English available . Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor, which are sensitive to label and product, thus ensure high accuracy and stable labeling performance. Greatly saves labor .

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions .

5) Machine Material: The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

6) Equip with a voltage transformerto adapt to local voltage.

Product detail pictures:

Related Product Guide:

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for Free sample for Lyophilized Powder Labeling Machine - FK803 Automatic Rotary Round Bottle Labeling Machine – Fineco , The product will supply to all over the world, such as: Guyana , Greek , Washington , We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!