Massive Selection for Manual Bottle Label Applicator Machine - FK911 Automatic Double-sided Labeling Machine – Fineco

Massive Selection for Manual Bottle Label Applicator Machine - FK911 Automatic Double-sided Labeling Machine – Fineco Detail:

FK911 Automatic Double-sided Labeling Machine

You can set video sharpness in the lower right corner of the video

Machine Description:

FK911 automatic double side labeling machine has additional functions to increase options:

① An optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

② Automatic feeding function (combined with product consideration);

③ Automatic material collection function (combined with product consideration);

④ Increase labeling device;

4. Automatic material collection function (combined with product consideration);

5. Increase labeling device;

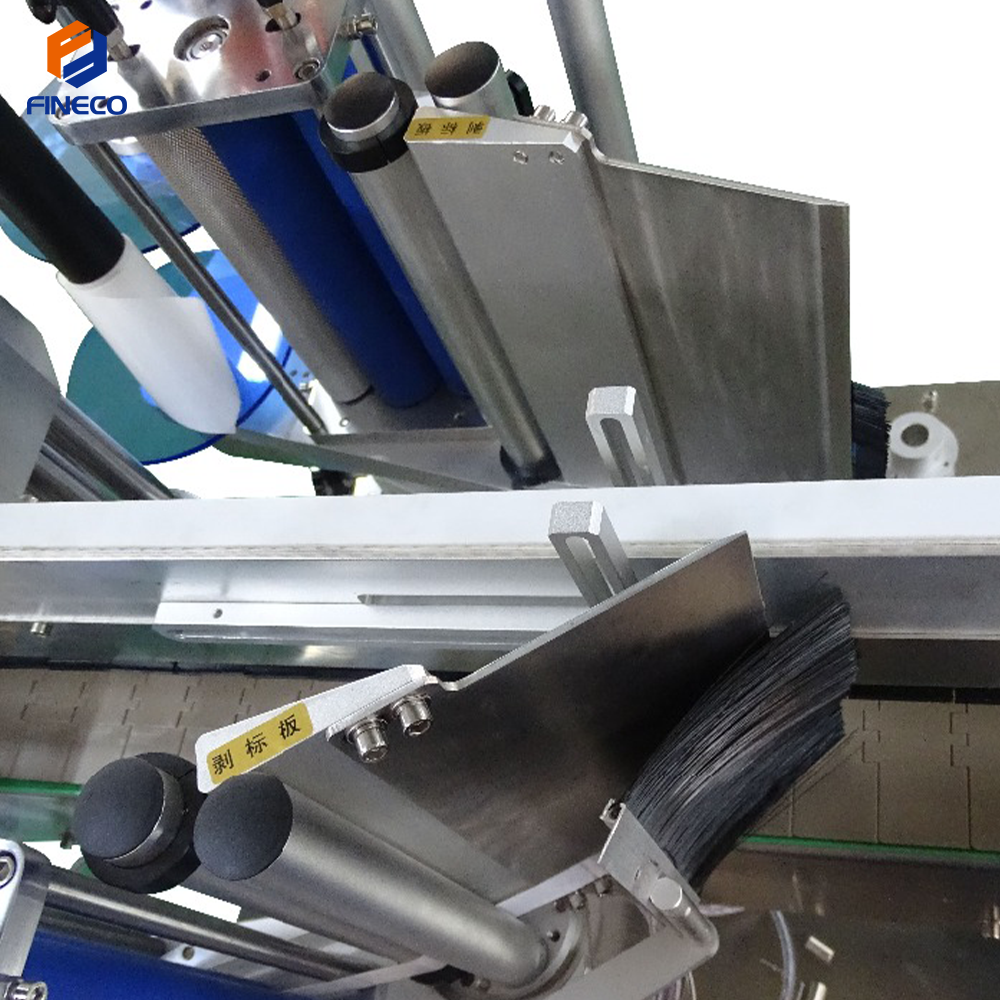

④ FK815 Adjust method is simple: 1.Adjust the height of the labeling mechanism, make the labeling knife edge higher 2mm than product height and at the same level. 2.Adjust the top conveyor belt, bottom conveyor belt and labeling speed on the touch screen so that they want to match. 3. Adjust the position of the sensor so that each label can be completely run out. 4.Adjust the height of the roller, let roller slight touch the labeling surface of the product.5.Adjust the position of the brush, make the brush just in touch with the product labeling surface.

⑤ FK815 floor space about 2.75 stere.

⑥ Machine Support Customization.

The FK815 Corner labeling machine has simple adjustment methods, high labeling accuracy and good quality, Applicable to the requirements of high precision, high output products, and it is difficult to see the error with the naked eye.

Working Principle:

1. Click star on the touch screen.

2. The product placed next to the guardrail, then the conveyor belt moves the products forward.

3. When the sensor detects that the products has reached target location, the machine will send out the label and the roller attaches half of the label to the product.

4. Then when the products is labeled and reaches a certain position, the brush will pop out and brushes the other half of the label onto the product, achieve corner labeling.

Label Specification:

① Applicable labels: sticker label, film, electronic supervision code, bar code.

② Applicable products: Products that are required to be labeled on flat, arc-shaped,round, concave, convex or other surfaces.

③ Application industry: Widely used in cosmetics, food, toys, chemical, electronics, medicine and other industries.

④ Application examples: shampoo flat bottle labeling, packaging box labeling, bottle cap, plastic shell labeling, etc.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Technical Parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance | ±1mm |

| Capacity(pcs/min) | 30~180 |

| Suit bottle size(mm) | L:40~400; W:40~200 H:0.2~150;Can be customized |

| Suit label size(mm) | L:6~150;W(H):15-130 |

| Machine Size(L*W*H) | ≈3000*1450*1600(mm) |

| Pack Size(L*W*H) | ≈3050*1500*1650(mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 2000W |

| N.W(KG) | ≈330.0 |

| G.W(KG) | ≈400.0 |

| Label Roll | ID:>76mm; OD:≤280mm |

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Massive Selection for Manual Bottle Label Applicator Machine - FK911 Automatic Double-sided Labeling Machine – Fineco , The product will supply to all over the world, such as: Pakistan , Nepal , New York , We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!