New Fashion Design for Disinfectant Labeling Machine - FK835 Automatic Production Line Plane Labeling Machine – Fineco

New Fashion Design for Disinfectant Labeling Machine - FK835 Automatic Production Line Plane Labeling Machine – Fineco Detail:

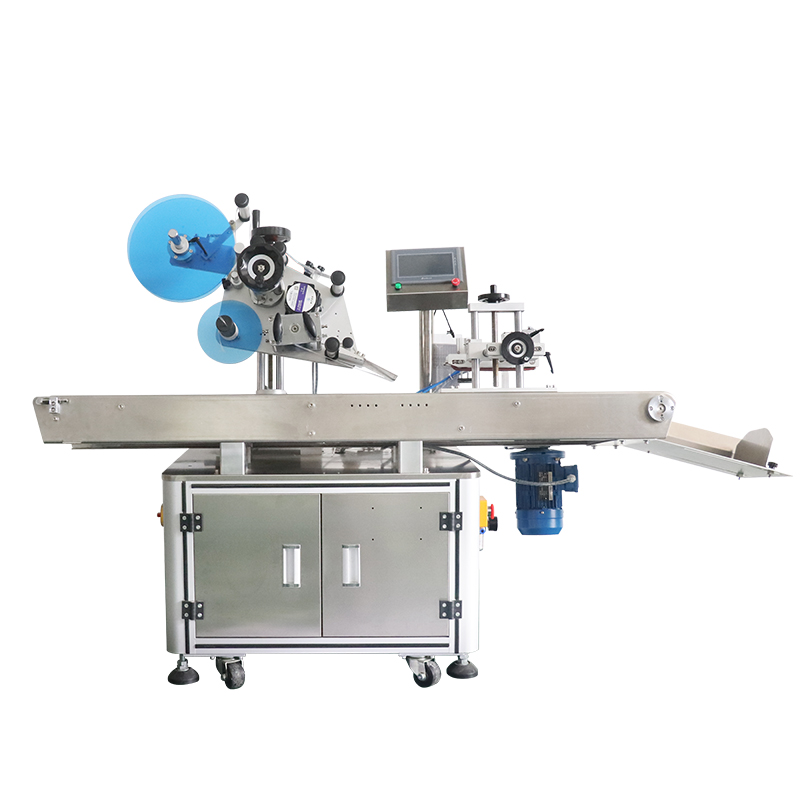

FK835 Automatic Production Line Plane Labeling Machine

Machine Description:

FK835 automatic line labeling machine has additional functions to increase options:

1. An optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensoSupport custom labeling machine according to the product.

Work Process:

working principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the labeling position of the product. The product passes the labeling roller, and a label The attaching action is completed.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Technical Parameters:

◆ Labeling accuracy (mm): ±1mm(errors caused by product and label are not concerned)

◆ Labeling speed (pcs / min): Step:40~150pcs/min Servo:50~200pcs/min (influenced by the size of the product and label)

◆ Applicable Product Diameter: No requirement.(Depend on assembly line convey parameter)

◆ Suitable label size(mm): length: 10mm~250mm: Width: 10mm~120mm

◆ Applicable power supply: 220V/50HZ

◆ Weight (kg): about 70kg

◆ Applicable standard roll Inner diameter (mm): φ76mm

◆ Applicable standard roll Outer diameter (mm): φ300mm

◆ Power (W): 330W

◆ Device dimensions (mm) (L × W × H): about 1100mm × 700mm ×1450mm

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for New Fashion Design for Disinfectant Labeling Machine - FK835 Automatic Production Line Plane Labeling Machine – Fineco , The product will supply to all over the world, such as: Canberra , Costa rica , Adelaide , Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.