Newly Arrival Label Finishing Machine - FKP-601 Labeling Machine With Cache Printing Label – Fineco

Newly Arrival Label Finishing Machine - FKP-601 Labeling Machine With Cache Printing Label – Fineco Detail:

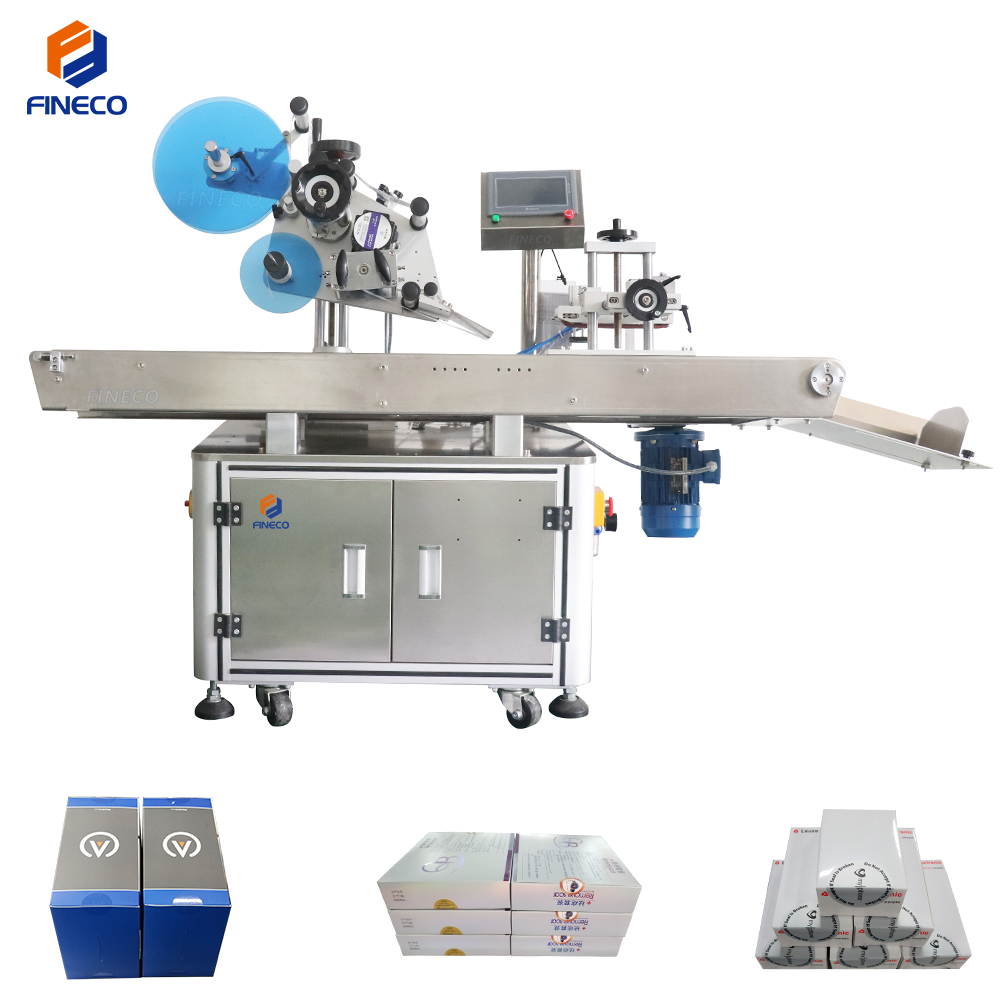

FKF601 Labeling Machine with cache printing label

You can set video sharpness in the lower right corner of the video

Machine Description:

FKP-601 Online Cache Print Labeling Machine has additional functions to increase options:

1. An optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date are printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

FKP-601 Online Cache Print Labeling Machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FKP-601 Online Cache Print Labeling Machine covers an area of about 2.38 cubic meters.

Support custom labeling machine according to the product.

Technical Parameters:

| Parameter | Data |

| Label Specification | adhesive sticker, transparent or opaque |

| Labeling Tolerance(mm) | ±1 |

| Capacity(pcs/min) | 15 ~40(According to product size) |

|

Suit product size(mm) |

L: 50 ~ 1500; W:20 ~ 300; H:≥0.2 (Can customization) |

| Suit label size(mm) | L: 50 ~ 250; W(H): 10 ~ 100(Can customization) |

| Machine Size(L*W*H)(mm) | ≈1650*900*1400 |

| Pack Size(L*W*H) (mm) | ≈1700*950*1450 |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power(W) | 1020 |

| N.W (KG) | ≈220 |

| G.W(KG) | ≈240 |

| Label Roll | ID: >76; OD:≤280 |

Labeling Process:

Put products in the feeding device→ The products are separated one by one → The products are transmitted by the conveyor belt → The product sensor detects the product→The PLC receives the product signal and sends it to the printing system to print the label→ PLC receives the product signal and start labeling→ the conveyor belt send the labeled products to the collecting plate.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Newly Arrival Label Finishing Machine - FKP-601 Labeling Machine With Cache Printing Label – Fineco , The product will supply to all over the world, such as: Australia , Hongkong , Turkey , Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!