Short Lead Time for Automatic Labeling Machine For Box Corner - FK Big Bucket Labeling Machine – Fineco

Short Lead Time for Automatic Labeling Machine For Box Corner - FK Big Bucket Labeling Machine – Fineco Detail:

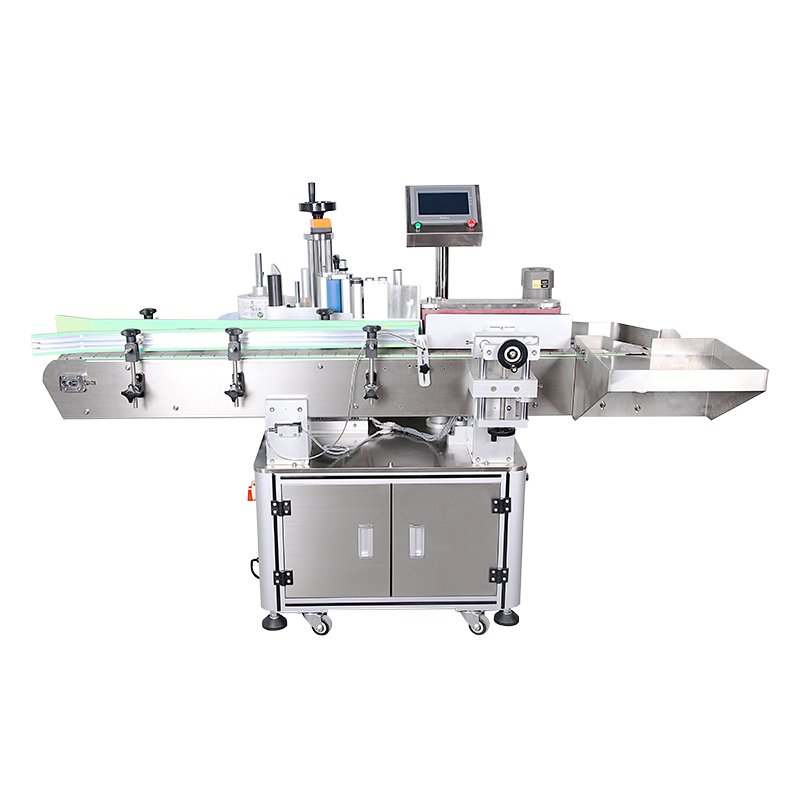

FK Big Bucket Labeling Machine

Parameter:

|

U |

220 V |

|

KW |

990W |

|

Bar |

0.3—0.6 Mpa |

|

Weight |

About:140KG |

|

power |

available 220V/50HZ |

|

machine size |

850 mm * 410 mm *720 mm |

|

label diameter |

Φ76mm-240 mm |

|

Labeling tolerance |

±0.5 mm |

|

label size limit(MM) |

L 6 -150 mm W 15-130 mm |

|

prodcution listing size |

L 20 -200 mm W 20-150 mm T 20 -320 mm |

|

Labeling speed to up |

15-30 /PCS /minute |

Machine Description:

FK Big Bucket Labeling Machine,It is suitable for labeling or self-adhesive film on the upper surface of various items, such as books, folders, boxes, cartons, toys, bags, cards and other products. The replacement of the labeling mechanism can be suitable for labeling on uneven surfaces. It is applied to the flat labeling of large products and the labeling of flat objects with a wide range of specifications.

The FK Big Bucket Labeling Machine has additional functions to add options:

① Optional ribbon coding machine can be added to the labeler head, print production batch,Date of manufacture and expiry at the same time.Realize in labeling-printing integration, greatly improve production efficiency.

② Optional inkjet machine to conveyor to print production date, batch number, and expiry date before or after labeling.

The FK Big Bucket Labeling Machine Semi-automatic labeling machine for large round barrels and tapered barrels with curvature,It has simple adjustment methods, high labeling accuracy and good quality, Applicable to the requirements of high precision, high output products,and it is difficult to see the error with the naked eye.

FK Big Bucket Labeling Machine covers an area of about 0.25 cubic meters

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Short Lead Time for Automatic Labeling Machine For Box Corner - FK Big Bucket Labeling Machine – Fineco , The product will supply to all over the world, such as: Pakistan , Qatar , Oslo , Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.